Hydrogen Storage using Metal Organic Frameworks

University of Texas at Dallas Summer 2009Hydrogen is an exciting option for an energy carrier because it is clean, quick to refuel,

and sustainable. But hydrogen storage requires high pressure or liquefaction, both of which

have safety, space efficiency, and energy efficiency concerns. New materials are being

developed that allow for hydrogen to be stored on the surface or within solids. Metal

Organic Frameworks (MOFs) are a class of commonly available and customizable lattice

structures that have strong potential for hydrogen adsorption and retention because they are

porous and have metal centers that the hydrogen can attach to.

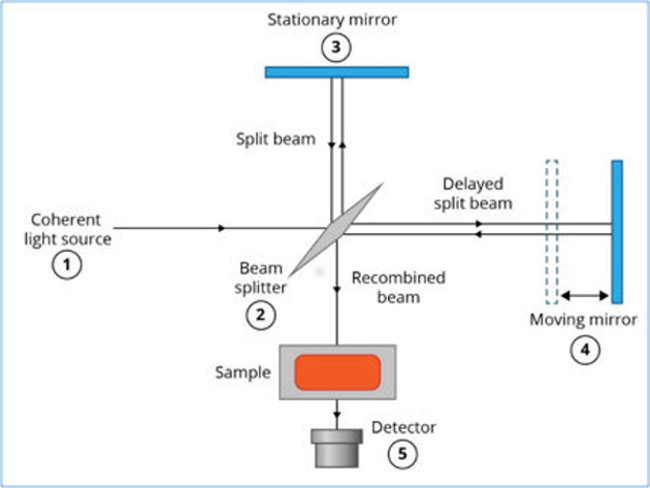

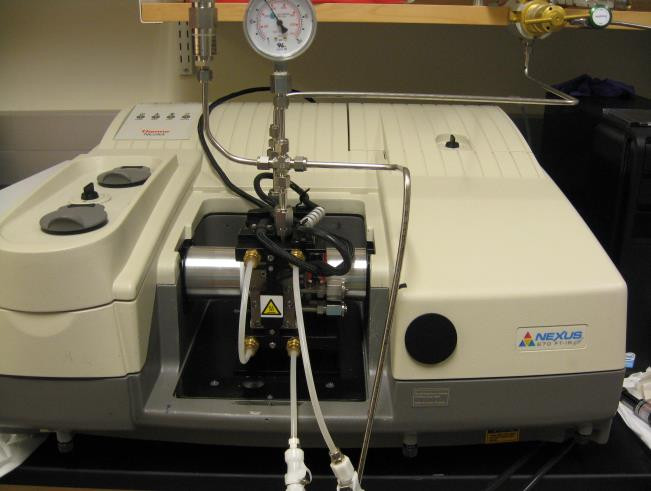

I supported two different research projects at the Laboratory for Surface and Nanostructure

Modification at UT Dallas under Dr. Yves Chabal. My activities involved synthesis of pellets

of MOFs, construction of a fuel cell apparatus for testing MOFs under pressurized hydrogen

and deuterium, and running adsorption trials using FTIR spectroscopy.

In the first project, the goal was to remove solvent leftover from production from the MOF

structures in a more effective way. Usually solvent removal is done by replacing the

existing solvent with one that has a lower boiling point, and then evaporating the new

solvent. But if not chosen carefully, the replacement solvents can have high surface

tensions, which can destroy the framework. We used supercritical CO2 as a replacement

solvent and adjusted temperature and pressure levels to minimize structural damage.

The second project involved trying to modify the MOF to retain hydrogen adsorption levels

after pressure is removed from the fuel cell. To do this, a process called atomic layer

deposition was used to deposit single atom layers of ruthenium metal onto the MOF. After

analyzing the modified MOF structure, the ruthenium deposition was not verified to have

occured during my time at the lab.

Recognition